Shipping (Fishing

Vessels of 24 Metres in Length and Over) (Safety Provisions) (Jersey)

Order 2004[1]

PART 1

PRELIMINARY

1 Interpretation

In this Order, unless the context otherwise requires –

“ ‘A’ class division” means a bulkhead

or part of a deck which is –

(a) constructed

of steel or other equivalent material;

(b) suitably

stiffened;

(c) so

constructed as to be capable of preventing the passage of smoke and flame to

the end of the 60 minute standard fire test; and

(d) so

insulated where necessary with suitable non-combustible materials such that, if

the division is exposed to the standard fire test, the average temperature of

the unexposed side of the division will rise not more than 139°C above the

initial temperature nor will the temperature at any one point, including any

joint, rise more than 180°C above the initial temperature within the time

listed below:

|

A - 60 standard...................................................

|

60 minutes

|

|

A - 0 standard.....................................................

|

0 minutes

|

“ ‘B’ class divisions” means those divisions

formed by bulkheads, decks, ceilings or linings which –

(a) are

so constructed as to be capable of preventing the passage of flame to the end

of the first 30 minutes of the standard fire test;

(b) have

an insulation value such that during the standard fire test the average

temperature of the unexposed side will not rise more than 140°C above its

initial temperature, nor will its temperature at any one point, including any

joint, rise more than 225°C above its initial temperature within the time

listed below:

|

B - 30 standard...................................................

|

30 minutes

|

|

B - 15 standard...................................................

|

15 minutes

|

|

B - 0 standard.....................................................

|

0 minutes

|

(c) except

in the case of divisions constructed of glass reinforced plastic, are

constructed of suitable non-combustible materials and their supporting members

or structures are also constructed of non-combustible materials;

“accommodation spaces” means corridors, lavatories,

cabins, offices, crew spaces, isolated pantries and similar spaces;

“breadth of a vessel” means the maximum width measured –

(a) to

the moulded line of the frame of a vessel with a metal shell;

(b) to

the outer surface of the hull of a vessel with a shell of any other material or

of a composite vessel;

“any ship or boat, or any other description of vessel used in

navigation; Class C boat” means a boat complying with the provisions of Article 85;

“collision orders” means international collision

orders relating to the avoidance of

collisions between ship that apply to Jersey ships;

“control stations” means spaces in which main navigating

or radio or central fire recording equipment or an emergency generator are

located;

“crew space” includes sleeping rooms, mess rooms,

sanitary accommodation, hospital accommodation, recreation accommodation, store

rooms and catering accommodation provided for the use of seamen but does not

include any accommodation which is also used by or provided for the use of

passengers;

“dead ship condition” means a condition where no power

is available in the vessel;

“distant water voyage” means a voyage during the course

of which a vessel proceeds outside the area bounded by lines adjoining the

following positions –

(a) coast

of Norway at 65° 00’N;

(b) 65°

00’N 8° 00’E;

(c) 61°

30’N 18° 00’W;

(d) 43°

00’N 18° 00’W;

(e) coast

of Spain at 43° 00’N;

“draught” means the vertical distance from the moulded

base line amid-ships to the operating water line of a vessel;

“enclosed superstructure” means a superstructure with –

(a) enclosing

bulkheads of efficient construction;

(b) access

openings, if any, in those bulkheads fitted with permanently attached

weathertight doors of a strength equivalent to the unpierced structure which

can be operated from either side; and

(c) other

openings in sides or ends of the superstructure fitted with efficient

weathertight means of closing, but does not include a bridge or poop unless

access is provided for the crew to reach machinery and other working spaces

inside the bridge or poop by alternative means which are available at all times

when bulkhead openings are closed;

“equivalent material” where the words are used in the

expression “steel or other equivalent material” means any material

which, by itself or due to insulation provided, has structural and integrity

properties equivalent to steel at the end of the standard fire test;

“fishing vessel” means a vessel which is for the time

being used for or in connection with sea fishing but does not mean a vessel

used for fishing otherwise than for profit;

“freeboard deck” means the uppermost complete deck

exposed to the weather and sea which has permanent means of closing all

openings in the weather portions thereof and below which all openings in the

sides of the vessel are fitted with permanent means of closing watertight. In a

vessel having a discontinuous freeboard deck, the lowest line of the exposed

deck and the continuation of that line parallel to the upper part of the deck

is to be taken as the freeboard deck.

A lower deck may be designated as the freeboard deck subject to its

being a complete and permanent deck continuous both –

(a) in a

fore and aft direction at least between the machinery spaces and peak bulkheads;

and

(b) athwart-ships.

When this lower deck is stepped, the lowest line of the deck and the

continuation of that line parallel to the upper part of the deck is to be taken

as the freeboard deck. When a lower deck is designated as the freeboard deck,

that part of the hull which extends above the freeboard is treated as

superstructure;

“height” in relation to a superstructure or other

erection means the least vertical distance measured at side from the top of the

deck beams of a superstructure or an erection to the top of the freeboard deck

beams;

“independent power pump” means a pump operated by power

otherwise than from the vessel’s main engines;

“inflatable boat” means a boat complying with Article 86;

“launching appliance” means the appliance complying with

Article 100;

“length” in relation to a vessel, means the length shown

on the vessel’s register and the “length overall” of a

fishing vessel shall be determined in accordance with the Tonnage Regulations;

“lifeboat” means a boat complying with Article 84;

“liferaft” means a liferaft complying with Article 87;

“machinery control room” means a room from which the propelling

machinery and boilers serving the needs of propulsion may be controlled;

“machinery space” in relation to vessels of 24 metres in

length and over means any space used for propelling, auxiliary or refrigerating

machinery, boilers, liver boilers, fish meal plant, pumps, engineers’

workshops, generators, ventilation or air conditioning machinery, oil filling

stations and similar spaces and trunkways to such spaces;

“main circulating pump” means the pump installed for

circulating water through the main condenser in steam driven vessels or the

pump which circulates the main engine sea water coolant in motor driven

vessels;

“maximum service speed” means the greatest speed which

the vessel is designed to maintain at sea at her deepest seagoing draught;

“motor lifeboat” means a lifeboat complying with Article 84(5);

“navigable speed” means the minimum ahead speed at which

the vessel can be effectively steered;

“non-combustible material” means a material which when

heated to a temperature of 750°C neither flames for longer than

10 seconds duration nor raises its internal temperature or the temperature

of the test furnace more than 50°C above 750°C when tested in

accordance with British Standard Specification 476; Part 4; 1970 and

the expression “combustible material” shall be construed

accordingly;

“oil fired boiler” means any boiler wholly or partly

fired by liquid fuel not being a domestic boiler of less than

73.28 kilowatts;

“oil fuel unit” means the equipment used for the

preparation of oil fuel for delivery to the oil burners of an oil-fired boiler

or that used to prepare heated oil for delivery to an internal combustion

engine and includes the oil pressure pumps, filters and heaters;

“person” means a person over the age of one year;

“principal length” means the length measured in metres

on a straight line from the fore part of the stem at top to the aftermost side

of the transom or stern contour;

“principal breadth” means the maximum breadth measured

in metres on a straight line to the outside of the frame lines of a vessel the

hull of which is constructed of metal or to the outer surfaces of a vessel the

hull of which is constructed of other material;

“principal depth” means the depth measured in metres at

the mid point of the principal length as the vertical distance from the top of

the deck beam at side to the top of the keel or line at the intersection of the

inside of the shell plating with the keel where a bar keel extends above that

line in a vessel the hull of which is constructed of metal or to the lower

rabbet line of the keel of a vessel the hull of which is constructed of other

material;

“service space” includes galleys, pantries, laundries,

store rooms, paint rooms, carpenters’ workshops and trunkways leading to

such spaces;

“settling tank” means an oil storage tank in which oil

fuel is heated in the course of its preparation for combustion in boilers and

machinery and which has a heating surface of not less than 0.18 square metres

per tonne of oil capacity;

“standard fire test” means a test in which specimens of

the relevant bulkheads or decks, having a surface area of not less than

4.6 square metres and a height of 2.4 metres, resembling as closely as

possible the intended construction and including, where appropriate, at least

one joint, are exposed in a test furnace to a series of time temperature

relationships, approximately as follows –

|

At the end of the first 5 minutes:

|

538°C

|

|

At the end of the first 10 minutes:

|

704°C

|

|

At the end of the first 30 minutes:

|

843°C

|

|

At the end of the first 60 minutes

|

927°C;

|

“steering gear power unit” means –

(a) in

the case of electric steering gear, the electric motor and its associated

electrical equipment; or

(b) in

the case of electro-hydraulic steering gear, the electric motor, its associated

electrical equipment and connected pump; or

(c) in

the case of steam-hydraulic or pneumatic-hydraulic steering gear, the driving

engine and connected pump;

“suitable” in relation to material means suitable for

the purpose for which it is used;

“superstructure” means a decked structure (including a

raised quarter deck) on the freeboard deck either extending from side to side

of the vessel or with the side plating not being inboard of the shell plating

more than 4% of the breadth of the vessel;

“superstructure deck” means that complete or partial

deck or the top of a superstructure, deckhouse or other erections situated at a

height of not less than 1.8 metres above the freeboard deck;

“surface spread of flame” means the surface spread of

flame classified as Class 1 or Class 2 within the meaning of British Standard

Specification 476: Part 7: 1997, or any British Standard Specification

that replaces it;

“vessel” includes any ship or boat, or any other

description of vessel used in navigation;

“vessel numeral” means the product obtained by

multiplying together the principal length by the principal breadth by the

principal depth;

“vivier boat” means a vessel that has a well having

access to the sea for the purposes of storing live shellfish;

“watertight” in relation to a structure means capable of

preventing the passage of water through the structure in any direction;

“weathertight” in relation to a structure means capable

of preventing the passage of sea water through the structure in ordinary sea

conditions.[2]

2 Application

This Order applies to every mechanically propelled fishing vessel of

24 metres in length and over registered under the Shipping (Jersey) Law 2002.[3]

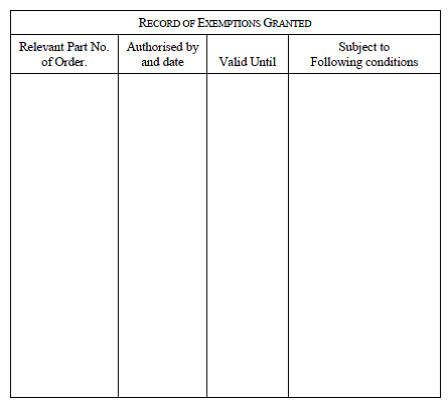

3 Exemption

The Minister may exempt any fishing vessel or description of fishing

vessel from any or all of the requirements of Part 2, either generally or

for a specified time or with respect to a specified voyage or to voyages in a

specified area, and may do so subject to any specified conditions.

PART 2

CONSTRUCTION OF FISHING

VESSELS

A – Hull (including

superstructures) and equipment

4 Structural

strength

(1) The structural strength

of every fishing vessel to which this Order applies and the number and

disposition of bulkheads shall be adequate for the intended service.[4]

(2) Every vessel shall be

provided with a watertight collision bulkhead in the fore part of the vessel

and main and auxiliary machinery essential for the propulsion and safety of the

vessel shall be situated in a watertight machinery compartment, except that

vessels constructed substantially of wood may be provided with a wooden

bulkhead or bulkheads of solid and substantial construction separating the fish

hold from the rest of the vessel.

B – Watertight

integrity

5 Closing

arrangements

In every vessel to which this Order applies the number of openings

in the outer watertight structure of the vessel shall be as few as reasonably

practicable and shall be provided with effective closing arrangements where

required by the provisions of this Order.[5]

6 Doors

In every vessel to which this Order applies doors fitted in the

outer watertight structure shall be of substantial construction permanently and

strongly attached to the bulkhead and so framed, stiffened and fitted that the

whole structure of which they are part is of equivalent strength to the unpierced

bulkhead. They shall be capable of being closed weathertight by means of

gaskets and clamping arrangements or other equally effective means permanently

attached to the bulkhead or to the door and arranged so that they may be

operated from each side of the bulkhead.[6]

7 Hatchway

covers

(1) Subject to paragraph (2),

in every vessel to which this Order applies where hatchway covers are

constructed of wooden boards with waterproof covers –

(a) the

unsupported span of the wooden boards shall not exceed 1.5 metres;

(b) the

finished thickness of the wooden boards shall be not less than

4 millimetres for each 100 millimetres of unsupported span and the

width of their bearing surfaces shall not be less than 65 millimetres,

except that no wooden board shall have a finished thickness of less than

40 millimetres;

(c) a

waterproof cover of suitable material and of adequate strength shall be

provided for every hatchway and be capable of being secured in place in

accordance with sub-paragraphs (e) and (f);

(d) where

portable beams are provided to support hatchway covers the strength of such

beams shall be calculated using the assumed static loads given in paragraph (3)(a)

and the mechanical properties of the material used in the construction and such

beams shall be of adequate strength for their intended service;

(e) cleats

shall be set to fit the taper of the wedges, spaced 600 millimetres centre

to centre and at least 65 millimetres wide. The end cleats on each end or

side shall be not more than 150 millimetres from the hatch corners;

(f) an

adequate number of battens and wedges of efficient pattern and in good

condition shall be provided. The wedges shall be of tough wood or equivalent

material cut to a taper of not more than one in 6 and shall not be less than

12 millimetres thick at the toes;

(g) steel

bars shall be provided to ensure that each section of the hatchway covers can

be efficiently and independently secured after the waterproof covers have been

battened down;

(h) hatchway

covers shall be permanently marked to indicate their correct position.[7]

(2) [8]

(3) In every vessel to

which this Order applies where hatchway covers are constructed of material

other than wood –

(a) for

the purpose of strength calculations it shall be assumed that such covers are

subjected to the weight of cargo intended to be carried on them or to the

following static loads whichever is the greater –

(i)

(ii) 1.75

tonnes per square metre, where the length of the vessel is 100 metres or more.

For vessels of lengths more than 24 metres but not exceeding

100 metres the loads shall be determined by linear interpolation provided

that where a hatchway is situated on the superstructure deck in a position

abaft a point 0.25 of the principal length from the forward perpendicular, the

assumed loads may be reduced to not less than 75% of the requirement of this paragraph;

(b) where

such covers are constructed of mild steel, the maximum stress calculated using

the assumed static loads set out in sub-paragraph (a) when multiplied by

4.25 shall not exceed the minimum ultimate strength of the material. Under

these loads the deflections shall not be more than 0.0028 times the span;

(c) every

such cover constructed of material other than mild steel shall have strength

and stiffness equivalent to those required in the case of a cover of mild

steel;

(d) every

such cover shall be fitted with gaskets and clamping devices, or other equally

effective arrangements, sufficient to ensure weathertightness.[9]

8 Machinery

space openings

(1) In every vessel to

which this Order applies machinery space openings in exposed positions on the

freeboard deck shall be properly framed and efficiently enclosed by casings of

adequate strength and fitted with doors complying with the requirements of Article 6.[10]

(2) In every such vessel

every such opening, other than a doorway provided in a casing, shall be fitted

with covers of strength equivalent to the unpierced structure, and shall be

permanently attached thereto and capable of being closed weathertight.

(3) In every such vessel

where casings are not fitted the access openings to the machinery space shall

be closed in accordance with Article 9(1).

9 Other

deck openings

(1) In every vessel to

which this Order applies, flush deck scuttles of the screw, bayonet or

equivalent type and manholes may be fitted where these are essential for

fishing operations and shall be capable of being closed watertight and shall be

permanently attached to the structure, provided that such scuttles and manholes

may be effectively weathertight only when closed if their design, size and

disposition is such that no danger is likely to result from the absence of

complete watertightness.[11]

(2) In every such vessel an

efficient superstructure, deckhouse or companionway fitted with weathertight

doors or other equally effective closing arrangements shall be provided to

protect deck openings in the freeboard and superstructure decks other than

hatchways, machinery space openings, manholes and flush scuttles.

10 Ventilators

In every vessel to which this Order applies coamings of ventilators

shall be of substantial construction and capable of being closed weathertight

by devices permanently attached to the ventilator or adjacent structure

provided that, subject to the requirements of Article 61(1), weathertight

closing appliances need not be fitted to ventilators in which the coamings

extend more than 4.5 metres above the freeboard deck or more than

2.3 metres above the superstructure deck.[12]

11 Air

pipes

In every vessel to which this Order applies where air pipes to tanks

and other spaces below deck extend above the freeboard or superstructure decks

the exposed parts of the pipes shall be of substantial construction. Exposed

openings of air pipes shall be provided with efficient means of closing

weathertight permanently attached to the pipe or adjacent structure. Provision

shall be made to prevent excessive pressure on tank boundaries.[13]

12 Side

scuttles and skylights

(1) In every vessel to

which this Order applies side scuttles to spaces below the freeboard deck and

to enclosed superstructures, deckhouses or companionways on the freeboard deck

shall be fitted with hinged deadlights capable of being closed watertight.[14]

(2) In every such vessel

every side scuttle shall be fitted in a position such that its sill is above a

line drawn parallel to the freeboard deck at side having its lowest point one

metre above the highest load waterline.

(3) In every such vessel

side scuttles, glasses and deadlights shall be of substantial construction.

(4) In every such vessel

skylights leading to spaces below the freeboard deck shall be of substantial

construction and capable of being closed and secured weathertight, and with

provision for adequate means of closing in the event of damage to the inserts.

13 Side

openings

In every vessel to which this Order applies the number of openings

in the sides of the vessel below the freeboard deck shall be the minimum

compatible with the design and proper working of the vessel and such openings

shall be provided with closing arrangements of adequate strength to ensure

watertightness and the structural integrity of the surrounding structure.[15]

14 Inlets,

discharges, and scuppers other than deck scuppers

(1) In every vessel to

which this Order applies each discharge pipe leading through the hull from

spaces below the freeboard deck or from within an enclosed superstructure or

deckhouse on the freeboard deck shall have an automatic non-return valve and a

positive means of closure from an accessible position except that the

requirements of this paragraph shall not apply in those cases where the piping

of the scupper or discharge pipe is of substantial thickness and where the

entry of water into the vessel through the opening is not likely to lead to

dangerous flooding.[16]

(2) In manned machinery

spaces in every such vessel controls for main and auxiliary machinery, sea

inlets and discharges shall be readily accessible and be provided with

indicators showing whether the valves are open or closed. In unmanned machinery

spaces suitable warning devices shall be installed to indicate leakage of water

into the space or leakage from any other system.

(3) In every such vessel

valves and other fittings attached to the hull shall be of steel, bronze or

other ductile material and pipes between the hull opening and the valve shall

be of steel except that in positions elsewhere and in vessels constructed of

materials other than steel, other materials may be used provided that they are

suitable for their intended service.

15 Heights

of hatchway coamings, doorways sills, ventilators and air pipes

(1) Subject to paragraph (2),

in every vessel to which this Order applies every hatchway on the freeboard

deck shall have a coaming of substantial construction and the height of the

coaming above the deck shall be not less than –

(a) 300 millimetres

for vessels with vessel numerals up to and including 200;

(b) 380 millimetres

for vessels with vessel numerals above 200 but no more than 315;

(c) 460 millimetres

for vessels with vessel numerals above 315 but not more than 1400;

(d) 600 millimetres

for vessels with vessel numerals above 1400.

On superstructure decks the height of the coamings shall be not less

than 300 millimetres.[17]

(2) In any such vessel the

height of hatch coamings specified in paragraph (1) may be reduced, or the

coamings omitted, where compliance with the requirements of paragraph (1)

is not reasonably practicable provided watertight hatch covers are fitted. Such

covers shall be kept as small as reasonably practicable, be permanently

attached by hinges or equivalent means and capable of being rapidly closed and

battened down.

(3) In every such vessel

the height of sills above the level of the deck in doorways provided in

companionways, superstructures, deckhouses and machinery casings which give

access to parts of the deck exposed to the weather and sea from spaces below

the freeboard deck shall be not less than those specified for hatchway coamings

in paragraph (1) provided that the height of such sills above deck may be

reduced where there is no direct access to spaces leading below the freeboard

deck and where the deck houses, superstructures or companionways on the

freeboard deck are sub-divided internally.

(4) In every such vessel

the lowest point at which water might gain access through the air pipes shall

be not less than 760 millimetres above the freeboard deck or not less than

450 millimetres above the superstructure deck, provided that these heights

may be reduced where compliance with the requirements of this paragraph is not

reasonably practicable because of interference with fishing operations and

provided adequate closing arrangements are fitted.

(5) On the freeboard deck

of every such vessel the height above deck of ventilators, other than machinery

space ventilators, shall be not less than 900 millimetres and on

superstructure decks not less than 760 millimetres. The height of ventilators

of machinery spaces shall be as high as is reasonable and practicable.

(6) In every such vessel

the requirements of this Article shall apply in relation to the heights of

coamings, sills, air pipes and ventilators above an enclosed deck where water

may accumulate and present a hazard to the vessel as they apply in relation to

the heights of coamings, sills, air pipes and ventilators above the freeboard

deck or superstructure deck as the case may be.

16 Freeing

ports

(1) In every vessel to

which this Order applies where bulwarks on weather parts of the freeboard deck

form wells, the minimum freeing port area in square metres (in this Article

referred to as “A”) on each side of the vessel for each well on the

freeboard deck shall be determined in accordance with the following formula in

relation to the length and height of the bulwark in the well (in this Article

referred to as “1” and “h” respectively) as follows:

|

A = (1.0 + 3.5h) 1 x h

100

|

|

where 1 = length of the bulwark

in metres.

|

|

h = mean height of the bulwark

in metres.

|

Where side houses or superstructures fitted within the well

contribute positive buoyancy to the vessel, A may be reduced except that, where

such side houses or superstructures are discontinuous and provide pockets for

the accumulation of water, no reduction shall be made.[18]

(2) In any such vessel if the

well is on a deck whose minimum height at side above the deepest operational

waterline is equal to or greater than “R” metres, A may be

multiplied by the factor “f” where –

|

f = 1 - 0.5

( H - R )

(2.35 - R)

|

|

R = 0.95 + (L - 30)

0.9

(95)

|

|

H = minimum height in metres measured from the deepest operational

waterline to the lowest part of the deck at side upon which the well is

formed.

|

|

L = registered length in metres.

|

|

In no case shall the factor “f” be less than 0.75.

|

(3) In

any such vessel, A may include –

(a) the

area of those freeing ports with attached means of closing provided that the

freeing ports shall only be closed during fishing operations; and

(b) in

stern trawlers the apertures in and under the stern doors.

(4) In every such vessel freeing

ports shall be so arranged throughout the length of the bulwarks as to provide

an effective means of freeing the deck of water. Lower edges of freeing ports

shall be as near to the deck as is practicable. Freeing ports greater than

230 millimetres in depth shall be fitted with bars spaced not more than

230 millimetres apart or by other equivalent arrangements.

(5) In every such vessel

the arrangements provided in the well for the stowage of equipment and the

catch shall not impair the effectiveness of the freeing ports.

(6) In every such vessel

intended to operate in zones where icing occurs the means of closing freeing

ports when fitted shall be capable of being readily removed.

C – Freeboard and

stability

17 Freeboard

Every vessel to which this Order applies shall be so designed,

constructed and operated as to ensure that in all foreseeable operating

conditions the freeboard will be adequate to provide –

(a) compliance with the

stability criteria set out in Article 18;

(b) reasonable safety for

men working on deck;

(c) reasonable safety to

the vessel from the entry of water into enclosed spaces having regard to the

closing appliances fitted.[19]

18 Stability

Every vessel to which this Order applies shall in all operating

conditions and circumstances set out in paragraphs 10 and 11 of Schedule 3

and in all foreseeable operating conditions satisfy the following stability

criteria after due correction for the free surface effects of liquids in tanks –

(a) the area under the

curve of righting levers (GZ curve) shall not be less than –

(i) 0.055

metre-radians up to an angle of 30 degrees,

(ii) 0.090

metre-radians up to an angle of 40 degrees or such lesser angle of heel at

which the lower edges of any openings in the hull, superstructures, deckhouses

or companionways, being openings which cannot be closed weathertight, are

immersed,

(iii) 0.030

metre-radians between the angles of heel of 30 degrees and 40 degrees

or such lesser angle as defined in clause (ii);

(b) the righting lever (GZ)

shall be at least 0.20 metres at an angle of heel equal to or greater than

30 degrees;

(c) the maximum righting

lever (GZ) shall occur at an angle of heel not less than 25 degrees;

(d) in the upright position

the transverse metacentric height (GM) shall not be less than 0.35 metres;

provided that, for vessels engaged on single or twin boom fishing

the values of dynamic stability, righting lever and metacentric height given in

sub-paragraphs (a), (b) and (d) shall be increased by 20%.[20]

D – Boilers and

machinery

19 General

(1) In every vessel to

which this Order applies machinery, boilers and other pressure vessels shall be

of a design and construction adequate for the service for which they are

intended and be installed and protected so as to minimise any danger to persons

on board.[21]

(2) In every such vessel

machinery spaces shall be designed to provide safe and free access to all parts

of the machinery which may require servicing at sea.

(3) In every such vessel

means shall be provided to prevent overpressure in any part of the machinery,

boilers and other pressure vessels. Every boiler shall be provided with not

less than 2 safety valves except that only one safety valve may be fitted if,

having regard to the output or any other features of the boiler, adequate

protection against overpressure is thereby provided.

(4) In every such vessel

machinery spaces which will be periodically unattended at sea shall be provided

with proper alarm, detection and machinery control systems.

(5) Prior to installation

in every such vessel every boiler or other pressure vessel and its mountings

shall be subjected to a hydraulic test to a pressure suitably in excess of the

working pressure which will ensure it is adequate in strength and design for

the intended service, having regard to –

(a) the

design and the material of construction;

(b) its

intended purpose;

(c) the

working conditions under which it is intended to be used.

(6) In every such vessel

every boiler or other pressure vessel and its respective mountings shall be

maintained in an efficient condition.

(7) In every such vessel

suitable provision shall be made to facilitate the cleaning and inspection of

every pressure vessel.

20 Boiler

feed systems

(1) In every vessel to

which this Order applies every boiler which provides services essential for the

safety of the vessel or which could become dangerous by the failure of its feed

water supply, shall be provided with not less than 2 efficient and separate

feed water systems so arranged that either of the systems may be opened for

inspection or overhaul independently of the other. Means shall be provided

which will prevent over-pressure in any part of the systems.[22]

(2) In every such vessel

where it is possible for oil to enter the feed water system of a boiler,

arrangements shall be provided for interception of the oil in the feed water.

(3) In every such vessel

check valves, fittings and pipes in feed water systems shall be designed and

constructed to withstand, with an adequate factor of safety, the maximum

working stresses to which they may be subjected. Valves, fittings or pipes

shall, prior to installation, be subjected to hydraulic test suitably in excess

of the maximum working pressure of the boiler to which they are connected or of

the maximum working pressure to which the feed line may be subjected, whichever

shall be the greater.

(4) In every such vessel

boiler feed systems shall be maintained in an efficient condition and the feed

pipes shall be adequately supported.

(5) In every such vessel provision

shall be made to ensure that an adequate reserve of feed water is available.

21 Steam

pipe systems

(1) In every vessel to

which this Order applies steam pipes and fittings connected thereto through

which steam may pass shall be so designed and constructed as to withstand the

maximum working stresses to which they may be subjected, with an adequate

factor of safety, having regard to –

(a) the

material of which they are constructed; and

(b) the

working conditions under which they will be used.[23]

(2) Every steam pipe or

fitting for every such vessel shall, prior to being put into service for the

first time, be subjected to a hydraulic test to a pressure suitably in excess

of the working pressure having regard to the requirements of paragraph (1).

(3) In every such vessel

every such steam pipe or fitting shall be maintained in an efficient condition.

(4) In every such vessel

steam pipes shall be adequately supported and in such a manner to avoid damage

due to variation in temperature, vibration or otherwise.

(5) In every such vessel

means shall be provided for draining every steam range to ensure that the

interior of each pipe in the range is kept free of water and that water hammer

action will not occur under any foreseeable service conditions.

(6) In every such vessel

steam fittings, steam pipes, hot exhaust pipes and other hot surfaces shall be

adequately insulated.

(7) In every such vessel

steam and exhaust pipes shall not be led through hold spaces unless adequately

protected.

(8) In every such vessel,

where a steam range may receive steam from any source at a higher pressure than

it can withstand with an adequate factor of safety, an efficient reducing

valve, relief valve and pressure gauge shall be fitted.

(9) In every such vessel

flanges in steam pipe systems shall not be situated above or in the vicinity of

switchboards or other electrical equipment except that where this is not

practicable provision shall be made to prevent leakage damaging the equipment.

(10) In every such vessel, in

exhaust steam systems of machinery fitted with positive shut-off valves where

the systems are not designed for the maximum inlet pressure, relief valves of

sufficient capacity shall be fitted.

22 Machinery

(1) In every vessel to

which this Order applies main and auxiliary machinery essential for the

propulsion and safety of the vessel shall be provided with effective means of

control. The machinery shall be capable of being brought into operation from

the dead ship condition.[24]

(2) In every such vessel

where risk from over-speeding of machinery exists provision shall be made to

ensure that the safe speed is not exceeded.

(3) In every such vessel

where main or auxiliary machinery or any parts of such machinery are subject to

internal pressure such parts shall, prior to installation, be subjected to a

hydraulic test to a pressure suitably in excess of the working pressure having

regard to –

(a) the

design and the material of which they are constructed;

(b) the

purpose for which they are intended to be used;

(c) the

working conditions under which they are intended to be used,

and such parts shall at any time thereafter be capable of

withstanding such a test.

(4) In every such vessel,

main and auxiliary machinery essential for the safety and propulsion of the

vessel shall be maintained in an efficient condition.

23 Means

for going astern

Every vessel to which this Order applies shall have adequate power

for going astern to maintain proper control of the vessel in all foreseeable

service conditions.[25]

24 Shafts

In every vessel to which this Order applies every shaft shall be so

designed and constructed that it will withstand the maximum working stresses to

which it may be subjected, with a factor of safety which is adequate having

regard to –

(a) the material of which

it is constructed;

(b) the service for which

it is intended;

(c) the type and size of

prime mover or motor by which it is driven or of which it forms a part.[26]

25 Exhaust

systems

In every vessel to which this Order applies the exhaust pipes and

silencers of every internal combustion engine shall be adequately cooled or

lagged to protect persons on board the vessel.[27]

26 Air

pressure systems

(1) Every vessel to which this

Order applies in which machinery essential for the propulsion and safety of the

vessel is required to be started, operated or controlled solely by compressed

air, shall be provided with an efficient air system, including an adequate

number of air compressors and air storage receivers and shall be so arranged as

to ensure that an adequate supply of compressed air is available under all

foreseeable service conditions.[28]

(2) In every such vessel

where the main engines are provided with means for air starting, the total air

storage receiver capacity shall be adequate to start the main engine or engines

not less than 12 times successively if the engine is reversible or not

less than 6 times successively if the engine is non-reversible.

(3) In every such vessel

where only one air storage receiver is provided for starting the main engines

separate provision shall be made for the storage of compressed air necessary

for starting the main electric generating sets where these are provided with

means for air starting.

(4) In every such vessel

air pressure systems and their component parts, other than pneumatic control

systems, which are subjected to air pressure shall be designed and constructed

to withstand, with an adequate factor of safety, the maximum working stresses

to which they may be subjected. Prior to being put into service for the first

time, air pressure pipes and fittings in such a system shall be subjected to a

hydraulic test to twice the system’s maximum working pressure.

(5) In every such vessel

air pressure systems shall be maintained in an efficient working condition.

(6) In every such vessel

adequate pressure relief arrangements shall be provided to prevent overpressure

in any part of any such air pressure system, and shall also be provided where

water jackets of casings of air compressors and coolers might be subjected to

dangerous overpressure due to leakage into them from air pressure parts.

(7) In every such vessel

provision shall be made to drain the system and to reduce to a minimum the

entry of oil into any air pressure system.

(8) In every such vessel

provision shall be made to protect the system from the effects of internal

explosion.

(9) In every such vessel

discharge pipes from starting air compressors shall lead directly to the

starting air receivers. Starting air pipes from the air receivers to main or

auxiliary engines shall be separate from the compressor discharge pipe system.

(10) In every such vessel where an

air pressure pipeline may receive air from any source at a higher pressure than

it can withstand with an adequate factor of safety, an efficient reducing

valve, relief valve and pressure gauge shall be fitted.

(11) In every such vessel soldered

joints shall not be used in air pressure pipe lines.

27 Cooling

water systems[29]

(1) In every vessel of 24 metres

in length and over to which this Order applies where machinery essential for

the propulsion and safety of the vessel is dependent for its operation on an

efficient cooling water system, there shall be provided at least one

circulating pump and, except in the case of any emergency generator, provision shall

be made so that in the event of the failure of the pump an alternative pump is

available for the same duty. These pumps shall provide an adequate supply of

cooling water to the cooling system.[30]

(2) In every such vessel

the sea water suctions of cooling systems for essential internal combustion

machinery shall be provided with strainers which can be cleaned without

interruption of the supply of water.

(3) In every such vessel

provision shall be made to prevent overpressure in any part of the system and

to indicate the proper working of the system.

28 [31]

29 Oil

systems for lubricating, cooling and control[32]

(1) In every vessel of 24 metres

in length and over to which this Order applies where oil for lubrication,

cooling or operation of the main propelling machinery, gearbox and its

ancillary services is circulated under pressure, at least 2 pumps shall be

provided for the circulation of such oil where –

(a) the

output or combined output of the main engines exceeds 500 b.h.p.; or

(b) lubricating

oil under pressure is the only means of control of machinery for the propulsion

and safety of the vessel.

Each pump shall be adequate for circulating the lubricating oil.

Only one pump shall be required for an emergency generator.[33]

(2) In every such vessel

strainers which can be cleaned without interrupting the supply of such oil

shall be provided.

(3) In every such vessel

provision shall be made to prevent overpressure and to indicate proper

operation in every part of the system. Where the means of preventing overpressure

is a relief valve it shall be in a closed circuit.

(4) In every such vessel

flexible pipes in lubricating oil, cooling oil and hydraulic systems shall be

fit for their intended service.

(5) In every such vessel

oil level indicators in lubricating oil, cooling oil and hydraulic systems

shall be accurate and fit for their intended service and shall be of a type

which does not require piercing of the lower part of the tank. Tubular gauge

glasses shall not be fitted to lubricating oil or hydraulic oil tanks but

suitably protected gauges having flat glasses of substantial thickness and

self-closing fittings may be used.

(6) In every such vessel

oil pressure pipes in lubricating oil, cooling oil and hydraulic systems shall

be made of seamless steel, or other suitable material having flanged joints and

shall be properly installed and be led at such a height above the inner bottom

as will facilitate inspection and repair. Every such pipe, joint and its

fittings other than pipes, joints and fittings in hydraulic control systems,

shall, before being put into service for the first time, be subjected to a test

by hydraulic pressure to 2.8 kilogrammes force per square centimetre or to

twice the maximum working pressure, whichever is the greater, and shall at any

time thereafter be capable of withstanding such a test.

(7) In every such vessel

oil pipes in lubricating oil, cooling oil and hydraulic systems, not being oil

pressure pipes, shall be made of steel or other suitable material having

flanged joints and shall be properly installed and be led at such a height

above the inner bottom as will facilitate inspection and repair. Every such

pipe, joint and its fittings other than pipes, joints and fittings in hydraulic

control systems, shall, before being put into service for the first time, be

subjected to a test by hydraulic pressure to 2.8 kilogrammes force per

square centimetre or to twice the maximum working pressure, whichever shall be

the greater, and shall at any time thereafter be capable of withstanding such a

test.

30 [34]

31 Oil

fuel installations (boilers and machinery) – general

(1) In every vessel to

which this Order applies oil fuel used in boilers or machinery shall have a

flash point of not less than 60°C (Closed Test), except that where the

emergency source of electrical power is a generator driven by internal

combustion type machinery having an independent fuel supply and with efficient

starting arrangements, the oil fuel provided for this machinery shall have a

flash point of not less than 43°C.[35]

(2) In every such vessel

oil fuel tanks which are not built into the vessel’s structure shall be

properly constructed and be provided with save-alls or gutters. These tanks

shall not be situated directly above boilers, heated surfaces, stairways, ladders,

or electrical equipment other than unbroken runs of cable. Prior to

installation these tanks shall be subjected to a hydraulic pressure test.

Storage tanks or service tanks shall be tested to a head of water 300 millimetres

in excess of the greatest head to which the tank may be subject when in

service. In the case of a settling tank the required head of water shall not be

less than 2.5 metres above the top of the tank.

(3) In every such vessel

adequate means shall be provided for sounding oil fuel tanks and means provided

to prevent overpressure in such tanks. The sounding arrangements or oil level

indicating gear fitted to settling tanks or daily service tanks shall not

permit the escape of oil if these tanks are overfilled. Oil level indicators

shall not allow oil to escape in the event of their being damaged.

(4) In every such vessel

air pipes shall be led from oil fuel tanks to the open air and the outlet shall

be situated so that there will be no danger of fire or explosion resulting from

the emergence of oil vapour from the pipe. Pipes shall be fitted with

detachable wire gauze diaphragms of non-corrodible material.

Where pipes also serve as overflow pipes provision shall be made to

prevent the overflow running into or near a boiler room, galley or other space

where ignition may occur.

(5) In every such vessel

air pipes from oil fuel tanks and levelling pipes attached to tanks shall have

a nett cross-sectional area not less than 1.25 times that of the filling

pipes.

(6) In every such vessel

self-closing type drains shall be provided for the removal of water from oil

fuel in storage tanks or settling tanks or in oily water separators.

(7) In every such vessel

pipes connected to any oil fuel storage, settling, or daily service tank, not

being a double bottom tank, shall be fitted with a valve or cock which shall be

secured to the tank to which it is connected and be capable of being closed

from a readily accessible position outside the space in which the tank is

situated provided that an inlet pipe may be fitted with a non-return valve

secured to the tank.

(8) In every such vessel

valves forming part of the oil fuel system shall be designed and constructed to

prevent the cover of the valve chest being slackened back or loosened when the

valve is operated.

(9) In every such vessel

pumps forming part of the oil fuel system shall be separate from the feed

pumps, bilge pumps and ballast pumps and the connection of any such pumps, and

shall be provided with an efficient relief valve which shall be in closed

circuit.

(10) In every such vessel the

means provided for the storage, distribution and utilisation of the fuel shall

be such that the effective use of the engines can be maintained under all

foreseeable service conditions.

(11) In every such vessel where

steam is generated for main propulsion or essential auxiliary machinery by

burning oil fuel under pressure, not less than 2 oil fuel units shall be

provided, each comprising a pressure pump, filters and a heater. The pump,

filters and heater shall be of efficient design and substantial construction.

Provision shall be made to prevent overpressure in any part of the oil fuel

units. The parts of these oil fuel units which are subjected to oil pressure

and the joints thereof shall, before being put into service for the first time,

be subjected to a test by hydraulic pressure to 28 kilogrammes force per

square centimetre or twice their maximum working pressure, whichever is the

greater, and shall at any time thereafter be capable of withstanding such a

test. Relief valves fitted to prevent over-pressure in the oil fuel heater

shall be in closed circuit. Where steam is used for heating oil fuel in

bunkers, tanks, heaters or separators, exhaust drains shall be provided to

discharge the condensate into an observation tank fitted with a manually

controlled drain.

(12) In every such vessel where a

gravity oil fuel system is installed filters shall be provided and shall be

capable of being cleaned without interrupting the supply of fuel oil.

(13) In every such vessel

equivalent arrangements to those set out in paragraph (12) shall be

provided in the fuel supply lines to main and auxiliary oil engines.

(14) In every such vessel

save-alls or gutters shall be provided under every oil fuel pump, filter and

heater and in way of the furnace mouths to prevent escaping oil from coming

into contact with boilers or other heated surfaces.

(15) In every such vessel where

flexible pipes are fitted in such systems, they shall be fit for their intended

service.

(16) In every such vessel fuel supply

lines to main propulsion and essential auxiliary machinery shall be provided

with filters so constructed that they may not be opened during use.

32 Oil

fuel installations (boilers and machinery)[36]

(1) In every vessel of

24 metres in length and over to which this Order applies oil fuel shall be

effectively isolated from other liquids. The oil fuel pumping arrangements

shall permit the oil fuel to be transferred from any oil fuel storage tank or

settling tank into another oil fuel storage tank or settling tank. Provision

shall be made to prevent the accidental discharge or overflow of oil overboard.

If drinking water or boiler feed water is stored in a tank adjacent to an oil

fuel tank a coffer-dam shall be provided which will prevent contamination.[37]

(2) In every such vessel

oil fuel tank sounding pipes shall not terminate in crew accommodation, but

they may be installed in passage-ways.

(3) In every such vessel

oil fuel level indicators shall be accurate and fit for their intended service,

and shall be of a type which does not require piercing of the lower part of the

oil fuel tank. Tubular gauge glasses shall not be fitted to oil fuel tanks but

suitably protected gauges having flat glasses of substantial thickness and self

closing fittings may be used.

(4) In every such vessel

overflows from settling tanks and daily service tanks shall be led back to the

storage tanks or to an overflow tank and means shall be provided to indicate

when the tanks are overflowing.

(5) In every such vessel

where oil fuel tanks are alternatively used as liquid ballast tanks proper

means shall be provided to isolate the oil fuel and ballast systems.

(6) In every such vessel

oil fuel filling stations shall be isolated from other spaces and be adequately

drained and independently ventilated. Provision shall be made to prevent

over-pressure in oil-filling pipe lines.

(7) In every such vessel

oil fuel pressure pipes shall be made of seamless steel or other suitable

material having flanged joints and shall be properly installed and be led at

such a height above the inner bottom as will facilitate inspection and repair.

Every such pipe, joint and its fittings shall, before being put into service

for the first time, be subjected to a test by hydraulic pressure to 28 kilogrammes

force per square centimetre or to twice the maximum working pressure, whichever

is the greater, and shall at any time thereafter be capable of withstanding

such a test. Where such pipes are used for conveying heated oil they shall be

situated in a position above the platform in well-lighted parts of the boiler

room or engine room.

(8) In every such vessel

oil fuel pipes not being oil fuel pressure pipes shall be made of steel or

other suitable material having flanged joints and shall be properly installed

and be led at such a height above the inner bottom as will facilitate

inspection and repair. Every such pipe, joint and its fittings shall, before

being put into service for the first time, be subjected to a test by hydraulic

pressure to 3.5 kilogrammes force per square centimetre or to twice the

maximum working pressure, whichever shall be the greater, and shall at any time

thereafter be capable of withstanding such a test.

(9) In every such vessel

steam heating pipes which may be in contact with oil shall be made of steel

and, together with their joints, shall, before being put into service for the

first time, be subjected to a test by hydraulic pressure to twice the maximum

working pressure, and shall at any time thereafter be capable of withstanding

such a test.

(10) In every such vessel every

suction pipe from any oil fuel tank situated above an inner bottom within a

boiler room or engine room shall be fitted with a valve or cock secured to each

tank to which the pipe is connected. Every such valve or cock fitted to an oil

fuel suction pipe shall be so arranged that it may be closed both from the

compartment in which it is situated and from a readily accessible position

outside such compartment not likely to be cut off in the event of fire in that

compartment. If any oil tank filling pipe is not connected to an oil fuel tank

at or near the top of the tank, it shall be fitted with a non-return valve or

with a valve or cock secured to the tank to which it is connected and so

arranged that it may be closed from the compartment in which it is situated and

also from a readily accessible position outside such compartment not likely to

be cut off in the event of fire in that compartment.

(11) In every such vessel master

valves at the furnace fronts which control the supply of oil fuel to sets of

burners shall be of quick-closing type and fitted in a readily accessible and

conspicuous position. Provision shall be made to prevent oil from being turned

on to any burner unless the burner has been correctly coupled up to the oil fuel

supply line.

(12) In every such vessel

provision shall be made for oil fuel pressure pumps and transfer pumps to be

stopped from a position outside the compartment in which the pumps are

situated.

33 [38]

34 Oil

fuel installations (cooking ranges and heating appliances)

(1) In every vessel to

which this Order applies where cooking ranges or heating appliances within crew

spaces are supplied with fuel from an oil tank, the tank shall be situated

outside the space containing the cooking range or heating appliance and the

supply of oil to the burners shall be capable of being controlled from outside

that space. Ranges or burners using oil fuel having a flash point of less than

60°C (Closed Test) shall not be fitted. Means shall be provided to shut off

the fuel supply automatically at the cooking range or heating appliance in the

event of fire or if the combustion air supply fails. Such means shall require

manual resetting in order to restore the fuel supply.[39]

(2) In every such vessel

the oil tank supplying the cooking range or heating appliance shall be provided

with an air pipe leading to the open air, and in such a position that there

will be no danger of fire or explosion resulting from the emergence of oil

vapour from the open end of the pipe. The open end shall be fitted with a

detachable wire gauze diaphragm.

(3) In every such vessel

adequate means shall be provided for filling every such tank and for preventing

overpressure.

35 Ventilation

In every vessel to which this Order applies every space in which an

oil fuel tank or any part of an oil fuel installation is situated shall be

adequately ventilated.[40]

36 Liquefied

petroleum gas installations (cooking ranges and heating appliances)

(1) In every vessel to

which this Order applies installations using liquefied petroleum gas shall be

properly and safely fitted and fit for their intended service.[41]

(2) In every such vessel an

odoriser shall be added to the gas to enable the presence of gas to be detected

by smell, even when its concentration in air is below that of the lower limit

of flammability.

(3) In every such vessel

containers holding liquefied petroleum gas shall be securely stowed on deck or

in a well ventilated compartment situated on the deck, except that, where deck

stowage is not reasonably practicable, such gas containers may be stowed in

spaces below deck, provided that such spaces are adequately ventilated and

electrical equipment in such spaces is of flame-proof construction. Where

drainage is provided from compartments containing such gas containers, drains

shall lead directly overboard.[42]

(4) In every such vessel

spaces containing cooking ranges or heating appliances which use liquefied

petroleum gas shall not be fitted with openings leading directly below to

accommodation spaces or their passageways, except that where this is not

reasonably practicable and such openings are fitted mechanical exhaust

ventilation trunked to within 300 millimetres of the deck adjacent to the

appliance, together with adequate supply ventilation, shall be provided.

(5) In every such vessel

spaces where appliances consuming liquefied petroleum gas are used shall be

adequately ventilated.

(6) In every such vessel

mechanical ventilation systems fitted to any space in which such gas containers

or appliances are situated shall be of such design and construction as will

eliminate the hazards due to sparking. The ventilation systems serving spaces

containing such gas storage containers or gas-consuming appliances shall be

separate from any other ventilation system.

(7) In every such vessel

where such gas consuming appliances are fitted below deck and for galleys in

vessels of 60 metres in length and over mechanical exhaust ventilation

shall be provided.

(8) In every such vessel,

every space containing such a gas consuming appliance shall be provided with

gas detection and audible alarm equipment. The gas detection device shall be

securely fixed in the lower part of the space in the vicinity of the gas

consuming appliance. The alarm unit and indicating panel shall be situated

outside the spaces containing the gas storage and consuming appliances.[43]

(9) [44]

(10) In vessels to which this Order

applies a device shall be fitted in the supply pipe from the gas container to

the consuming appliance which will shut off the gas automatically in the event

of loss of pressure in the supply line. The device shall be of a type which

requires deliberate manual operation to re-set it to restore the gas supply. An

automatic shut-off device which operates in the event of flame failure shall be

fitted on all appliances consuming liquefied petroleum gas.[45]

37 Storage

of flammable liquids, toxic liquids, toxic gases and compressed gases

(1) In every vessel to

which this Order applies cylinders containing flammable, toxic or other

dangerous gases, and expended cylinders shall be properly stowed and secured on

open decks, and all valves, pressure regulators and pipes leading from such

cylinders shall be protected against damage. Such cylinders may be stowed in

compartments which meet the requirements set out in paragraph (2).[46]

(2) In every such vessel

highly flammable liquids, toxic liquids, toxic gases, and liquefied gases,

other than liquefied petroleum gas shall be stored in compartments having

direct access from open decks. Such compartments shall have boundary bulkheads

constructed from non-combustible materials. Pressure adjusting devices and

relief valves, if any, shall exhaust within the compartment. Where boundary

bulkheads of such compartments adjoin other enclosed spaces they shall be gas

tight and adequately insulated and provided with ventilation arrangements which

are separate from other ventilation systems. Ventilation shall be arranged at

high and low levels and the inlets and outlets of ventilators shall be

positioned in safe areas and fitted with spark arresters.

(3) In every such vessel

electrical wiring and fittings shall not be installed within compartments

containing highly flammable liquids or liquefied gases except where necessary

for service within the space. Where such electrical fittings are installed they

shall be suitable for use in a flammable atmosphere.

(4) In every such vessel

where cylinders containing flammable or other dangerous compressed gases are

carried below deck, cylinders containing one type of compressed gas shall be

stowed separately from cylinders containing another type. Compartments

containing cylinders of such compressed gases shall not be used for stowage of

other combustible products or for tools or objects not belonging to the gas

distribution system.

E – Bilge pumping

arrangements

38 Bilge pumping requirements for vessels[47]

(1) Every vessel to which this

Order applies shall be provided with –

(a) efficient

bilge pumping plant and means for drainage so arranged that water entering any

part of the hull, other than a space permanently appropriated for the carriage

of fresh water, water ballast, oil fuel or liquid cargo and for which other

efficient means of pumping or drainage are provided, can be pumped out through

at least one suction pipe when the vessel is upright or is listed not more than

5 degrees either way. Wing suction shall be provided if necessary for this

purpose. Arrangements shall be provided for an easy flow of water to the

suction pipes. Provided that where the safety of the vessel is not thereby

impaired, the bilge pumping arrangements may be dispensed with in any

particular compartment or compartments of any vessel or class of vessels;

(b) arrangements

for the drainage of all insulated compartments;

(c) not

less than 2 independent powered bilge pumps provided that –

(i) one such pump may

be driven from the main engine,

(ii) a

ballast pump or other general service pump of adequate capacity may be used as

an independent bilge pump,

(iii) a

properly installed bilge ejector in combination with a power driven pump may be

provided as a substitute for one independent power driven bilge pump.[48]

(2) In every such vessel –

(a) bilge

pumps shall be self-priming. Pumps, other than hand pumps of the lever type and

pumps provided for peak compartments only, shall, whether operated by hand or

by power, be capable of drawing water from any space required by paragraph (1)

to be drained;

(b) power

bilge pumps shall be capable of giving a speed of water of not less than

2 metres per second through the main bilge pipe when its diameter is that

determined by paragraph (5)(a). Each pump shall have a direct suction from

the space in which it is situated, provided that not more than 2 direct

suctions shall be required in any one space. The diameter of the direct suction

shall be not less than that of the main bilge pipe. The direct suctions in the

machinery space shall be so arranged that water may be pumped from each side of

the space through direct suctions to independent bilge pumps;

(c) one

of the sea water pumps circulating each main engine shall be fitted with

emergency bilge suction connexions, which shall be provided with non-return

valves, to the lowest drainage level in the machinery space, or as near thereto

as is reasonably practicable. In vessels powered by steam the diameter of these

connections shall be at least 2/3 of that of the main sea inlet. In motor

vessels these connexions shall be of the same diameter as the pump inlet. Where

any main circulating pump is not suitable for this purpose a direct emergency

bilge suction shall be led from the largest available independent power driven

pump to the drainage level of the machinery space. Such emergency suction shall

be of the same diameter as the main inlet of the pump used. The capacity of the

pump so connected shall exceed that of a required bilge pump by an adequate

amount. The open end of such suctions or the strainer, if any, attached thereto

shall be accessible for clearing. The spindles of the main sea inlet and the

direct suction valves shall extend well above engine room platform level;

(d) where

hand bilge pumps are fitted they shall be either rotary, semi-rotary or lever

operated and shall be operable from above the freeboard deck, and be so

arranged that the bucket and tail valve can be withdrawn at all times.

(3) In every such vessel

distribution boxes, valves and cocks fitted in bilge pumping systems shall be

in accessible positions.

(4) In every such vessel –

(a) pipes

from the pumps for draining hold spaces or any part of the machinery space

shall be independent of pipes which may be used for filling or emptying spaces

in which water or oil is carried;

(b) bilge

pipes in boiler or machinery spaces including spaces in which oil settling

tanks or oil fuel pumping units are situated shall be of steel or other

equivalent material;

(c) bilge

suction pipes shall not be led through double bottom tanks unless they are of

heavy gauge steel construction with a minimum number of joints and shall be

tested after fitting to a pressure of 3.5 kilogrammes force per square

centimetre;

(d) bilge

suction pipes shall be fitted with flanged joints and shall be properly secured

in position and provided with expansion joints or bends. Pipes situated in fish

holds, chain lockers or other positions where they are liable to damage shall

be adequately protected.

(5) In every such vessel –

(a) the

internal diameter of main and branch bilge suction pipes shall be determined to

the nearest 5 millimetres by the following formulae:

dm = 25 + 1.68 ÖL(B + D)

db = 25 + 2.15 ÖC(B + D)

where dm = internal diameter of the main bilge suction

pipes in millimetres;

db = internal diameter of the branch bilge suction pipes

in millimetres;

L = Principal length of vessel in metres;

B = Principal breadth of vessel in metres;

D = Principal depth of vessel in metres;

C = Length of compartment in metres;

(b) the

inside diameter of the bilge main and bilge suction directly connected to the

pump shall be not less than 50 millimetres;

(c) bilge

and ballast pumping systems shall be so arranged as to prevent water passing

from the sea or from water ballast spaces into holds or into machinery spaces

or from one watertight compartment to another. The bilge connection to any pump

which draws from the sea or from water ballast spaces shall be fitted with

either a non-return valve or a cock which cannot be opened simultaneously

either to the bilges and to the sea or to bilges and water ballast spaces.

Valves in bilge distribution boxes shall be of a non-return type;

(d) any

bilge pipes piercing a collision bulkhead shall be fitted with a screw-down

valve at the bulkhead with remote control from above the deck at which the bulkhead

terminates, with an indicator showing the position of the valve. If the valve

is fitted on the after side of the bulkhead and is readily accessible under all

service conditions the remote control may be dispensed with.

(6) In every such vessel

bilge suctions in the machinery space shall be led from readily accessible mud

boxes placed wherever practicable above the level of the working floor of the

space. The boxes shall have straight tailpipes to the bilges and covers secured

in such a manner as will permit them to be readily opened and closed. The

suction ends in hold spaces and tunnel wells shall be enclosed in strum boxes

having perforations approximately 10 millimetres in diameter, and the

combined area of such perforations shall be not less than twice that of the

suction pipe. Strum boxes shall be so constructed that they can be cleared

without breaking any joint of the suction pipe.

(7) In every such vessel –

(a) subject

to the requirements of sub-paragraph (b) the tanks forming part of the

structure of the vessel and all watertight compartments, not being part of the

machinery space, shall be provided with efficient sounding arrangements which

shall be protected where necessary against damage. Where such arrangements

consist of sounding pipes, a thick steel doubling plate shall be securely fixed

below each sounding pipe for the sounding rod to strike upon. All such sounding

pipes shall extend to readily accessible positions above the vessel’s

freeboard deck;

(b) sounding

pipes for bilges, coffer dams and double bottom tanks being bilges, coffer dams

and tanks situated in the machinery space, shall extend to readily accessible

positions above the vessel’s freeboard deck unless the upper ends of the

pipes are accessible in ordinary circumstances and are furnished with cocks

having parallel plugs with permanently secured handles so loaded that on being

released they automatically close the cocks. Sounding pipes for bilges shall

not be less than 65 millimetres in diameter.

39 [49]

F – Electrical

equipment and installation

40 General

In every vessel to which this Order applies electrical equipment and

installations including any electrical means of propulsion shall be such that

the vessel and all persons on board are protected against electrical hazards.[50]

41 Distribution

systems

(1) In every vessel to

which this Order applies main and emergency switchboards shall be suitably

guarded and so arranged as to provide easy access without danger to any person.

Adequate non-conducting mats or gratings shall be provided. Exposed parts which

may have a voltage between conductors or to earth exceeding 250 volts

direct current or 55 volts alternating current shall not be installed on

the face of any switchboard or control panel.[51]

(2) In every such vessel

hull return shall not be used for the power, heat and light distribution

systems.

(3) In every such vessel

where 2 or more generating sets may be in operation at the same time for

providing the auxiliary services essential for the propulsion and safety of the

vessel each generator shall be arranged to supply such essential services and

means shall be provided to trip automatically sufficient non-essential load

when the total current exceeds the connected generator capacity.

(4) In every such vessel

cable systems and electrical equipment shall be so installed as to reduce

interference with radio reception to a minimum.

42 Electrical

precautions

(1) In every vessel to

which this Order applies electrical equipment shall be so constructed and

installed that there will be no danger to any person handling it in a proper

manner –

(a) subject

to sub-paragraph (b), where electrical equipment is to be operated at a

voltage in excess of 55 volts the exposed metal parts of such equipment

which are not intended to have a voltage above that of earth, but which may

have such a voltage under fault conditions, shall be earthed;

(b) exposed

metal parts of portable electrical lamps, tools and similar apparatus, to be

operated at a voltage in excess of 55 volts shall be earthed through a

conductor in the supply cable unless, by the use of double insulation or a

suitable isolating transformer, protection at least as effective as earthing

through a conductor is provided.[52]

(2) In every such vessel

every fixed electrical cable shall be of a flame retarding type. All metal

sheaths and armour of any electric cable shall be electrically continuous and

shall be earthed. Electric cable which is neither metal sheathed nor armoured

shall, if installed where its failure might cause a fire or explosion, be effectively

protected.

(3) In every such vessel

wiring shall be supported in such a manner as to avoid chafing or other damage.

(4) In every such vessel

joints in all electrical conductors except those in low voltage communications

circuits shall be made only in junction or outlet boxes or by a suitable method

such that it retains the original mechanical, flame retarding and electrical